Our company history

2008

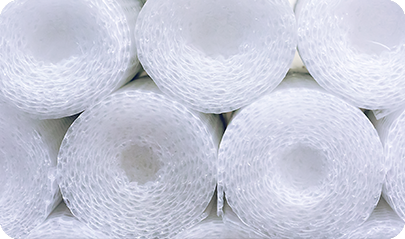

Start of bubble wrap production

2010

Launch of the second production line

2014

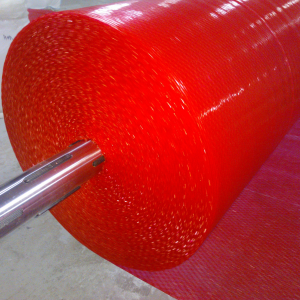

Launch of the third production line

2020

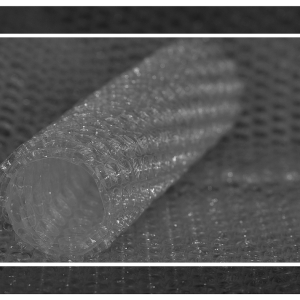

Purchase of a modern recycling line

2021

Installation of a photovoltaic system

2024

New production line

Kaszmir began its operations in 2005 in Szczecinek. Initially, we focused solely on running a wholesale business specializing in household appliances and supplies for florists, ranging from glassware and gifts to accessories for fresh flowers.

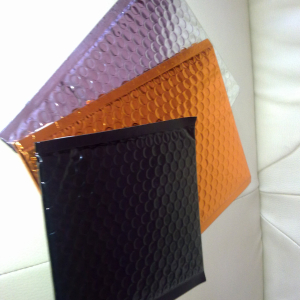

In 2007, we expanded our services to include international transportation. We continue to offer these services to this day. However, in the long term, our transportation operations will focus exclusively on distributing our own production—bubble wrap. We have been manufacturing bubble wrap since 2008, investing in a modern production line for three-layer film. Initially, we mainly produced packaging films used for wrapping. The distribution of our products followed two channels: wholesale and retail, the latter through the Allegro platform. In the following years, we tailored our production to meet the needs of bubble mailer manufacturers, shifting our focus to envelope film.

This change in production profile opened up opportunities for further growth and investment in additional production lines. Today, our machinery park enables us to produce millions of meters of film each month. We manufacture a wide range of both packaging films and envelope films. Ensuring the quality and consistency of our products is made possible by using the highest-quality raw materials and specialized equipment that guarantees the precise preparation of production blends.

Following our commitment to sustainability, in 2021, the company invested in renewable energy. Our own photovoltaic installation, generating 50 kWh, provides us with free energy. This has made us independent from external electricity suppliers while also contributing to the protection of our planet’s environment.

In 2023, we launched a modern production line for bubble wrap, capable of manufacturing two-layer and three-layer films, as well as bubble wrap with a 30/10mm bubble size, known as BK.

Environmental protection

With environmental care in mind, Firma Kaszmir has invested in a modern LDPE recycling line, which allows for 100% utilization of purchased raw materials.

By not producing foil waste, we do not pollute the environment!!!

70% recycled materials

A new investment based on the experience of raw material suppliers allows us to prepare a new, appropriate recipe with 70% recycled materials. Modern production methods allow for maintaining good, consistent quality.

Firma Kaszmir strives to care for our planet.